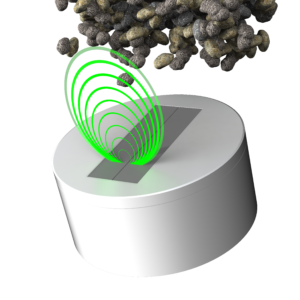

SONO-VARIO® sand moisture sensor can be installed on a conveyor belt or under a silo valve, measuring moisture levels accurately in all types of sand.

SONO-VARIO® Sand Moisture Sensor, a member of our SONO® sensor family, provides real-time moisture measurements for both fine and coarse sands. Designed for use on conveyor belts and under silos.

Accurate monitoring of sand moisture levels is crucial for optimizing operations in the construction and mining industry. The SONO-VARIO® moisture sensor, specifically designed to measure moisture content in various types of sand, provides users with full control over the final product quality.

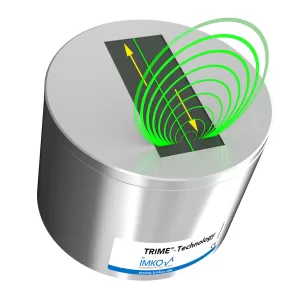

At the core of our SONO® sand moisture sensor lies the groundbreaking TRIME® TDR Technology. This patented innovation allows the sensor to be mounted directly onto the line, enabling the measuring field to continuously penetrate deep into a substantial volume of the moving material. This provides you with highly accurate and repeatable moisture measurements of 0.1% or better.

With over two decades of expertise, Seztec’s moisture probes meet all your sand moisture measurement needs, saving you time, energy, and money.

Whether for online process moisture measurement, concrete and asphalt production, ready-mix and pre-cast applications, our SONO-VARIO® sand moisture sensor delivers exceptional performance. It’s also perfect for highly conductive materials like Foundry Sand, Ore, Slag, and Coal.

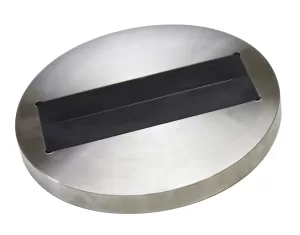

Unlike other sand moisture sensors on the market, SONO-VARIO® sand moisture sensor offers you the flexibility to replace its sensor head if it ever succumbs to abrasion, without the need to replace the entire probe. This not only extends your maintenance intervals but also saves you precious time and money.

Our SONO-VARIO® sand moisture sensor utilizes a 1 GHz TDR pulse with wave guides to generate an electromagnetic field, achieving a remarkable resolution of 1 picosecond in transit time measurement. Additionally, it features a built-in temperature sensor for real-time readings and automatic temperature compensation, ensuring accuracy of 0.1% or better.

Choose from 15 pre-programmed standard linear calibrations, allowing you to select the ideal setting for various sand and aggregate types, perfectly aligning with your sand moisture measurement requirements.

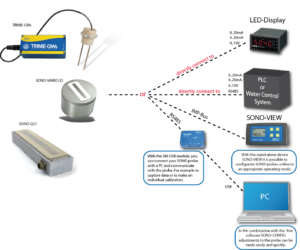

SONO-VARIO® sand moisture sensor offers a range of interface options, accommodating every data transfer need. Transfer parameters such as moisture content, conductivity, and temperature directly into your PLC. Alternatively, connect the probe to your local PC (USB port) using the SM-USB module or SONO-VIEW field display for individual parameter adjustments and calibrations.

For highly abrasive aggregates such as gravel, rock, crushed stone and RAP (Reclaimed Asphalt Pavement), up to 1-1/4 inch, our SONO VARIO – Xtrem Moisture Sensor will be suitable. Contact us to find the right sensor for your application.

| Measured Parameters | Moisture Content %, Temperature, Conductivity |

| Technology | TDR (Time Domain Reflectometry) |

| Sensor Body | Casing: High Grade Steel V2A 1.4301 |

| Sensor Head | The probe head surface consists of stainless steel with abrasion-resistant aluminium oxide ceramic. |

| Moisture Measurement Range | The sensor measures from 0% up to the point of material saturation. Measurement ranges up to 100% moisture (pure water) are possible with a special calibration. |

| Conductivity Measurement Range | The sensor, as a material-specific characteristic value, delivers the radar-based conductance (ECTRIME) in a range of 0…12dS/m. |

| Temperature Measurement Range | Measurement range: 0°C …70°C (150°C on request). |

| Accuracy | Better than 0.1% for most applications. |

| Analog Outputs | 2 x Analogue Outputs 0(4)…20mA |

| Factory Calibrated | The sensor is provided with a universal calibration for sand. A maximum of 15 different calibrations can be stored. |

| Power Supply | +12V to max. +24V-DC, 3W |

Key Advantages

› Exchangeable sensor head with wear-resistant steel/ceramic window.

› Auto-correction function: the probe recalibrates itself in the event of abrasion at the probe head.

› Up to 15 different material calibration curves are directly stored inside the probe.

› Intelligent pre-processing inside the probe with smooth mean value accumulation and powerful adjustable filters.