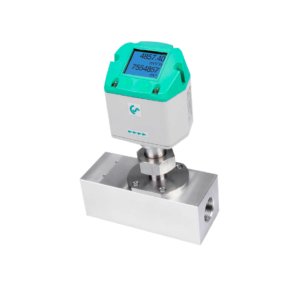

Reliable compressed air flow meter to measure mass flow in compressed air and other gas systems.

VA521 compressed air flow meters are based on the thermal dispersion principle, according to which the rate of heat absorbed by a flowing medium flowing through a pipe is directly proportional to its mass flow.

The newly developed VA 521 combines modern digital interfaces for connection to an energy monitoring system with a small, compact design. The VA 521 is always used when many machines (compressed air consumers) are to be integrated into an energy monitoring network.

Flow sensor with integrated flow straightener / no inlet sections necessary

The newly developed VA 521 combines modern digital interfaces for connection to an energy monitoring system with a small, compact design. The VA 521 is always used when many machines (compressed air consumers) are to be integrated into an energy monitoring network.

The high-contrast, integrated display also displays the current values rotated by 180° if desired (very useful for overhead installation). Depending on the configuration, two of the following values can be displayed:

› Current consumption in m³/h, l / min, …

› Total consumption (meter reading) in m³, l, kg

› Temperature measurement

The advantages at a glance:

› Screw thread for easy installation in existing piping through integrated measuring block (suitable for 1/2“, 3/4 ̋, 1“, 1 1⁄4 ̋, 1 1⁄2“ or 2″ lines)

› Compact, small design – for use in machines, behind maintenance unit at the end user

› All interfaces are programmable via the display

› Modbus RTU output

› 4…20mA analog output for actual flow

› Pulse output total flow (counter reading), galvanically isolated. Optionally › M-Bus, Ethernet-Interface, or PoE

| Parameters | m³/h, l/min (1000 mbar, 20 °C) in case of compressed air or Nm³/h, Nl/min (1013 mbar, 0 °C) in case of gases |

| Units adjustable via keys at display | m³/h, m³/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min, g/s, lb/min, lb/h |

| Sensor | Thermal mass flow sensor |

| Measured medium | Air, gases |

| Gas types are adjustable over CS service software or CS data logger | Air, nitrogen, argon, CO2, oxygen |

| Accuracy | ± 1.5% of m.v. ± 0.3 % of f.s |

| Operating temperature | -30…80 °C |

| Operating pressure | Up to 16 bar, optionally 40 bar |

| Supply Power | 18…36 VDC, 5 W |

| Outputs | MODBUS RTU, 4..20mA, Pulse |

› Screw thread for easy installation in existing piping through integrated measuring block (suitable for 1/2“, 3/4 ̋, 1“, 1 1⁄4 ̋, 1 1⁄2“ or 2″ lines)

› Compact, small design – for use in machines, behind maintenance unit at the end user

› All interfaces are programmable via the display

› Modbus RTU output

› 4…20mA analog output for actual flow

› Pulse output total flow (counter reading), galvanically isolated. Optionally › M-Bus, Ethernet-Interface, or PoE