Ultraflux Uf801 clamp-on water flow meter measures flow of liquids from outside the pipe. Non-contact portable flow meter.

The Ultraflux Uf 801P Clamp-On Water Flow Meter is a reliable, non-intrusive external flow meter with sturdy IP68 body. It accurately measures water flow rates in pressurized pipes. This non-invasive flow meter is versatile and compatible with a diverse range of liquids, including water, chemicals, toxic media, or hydrocarbons.

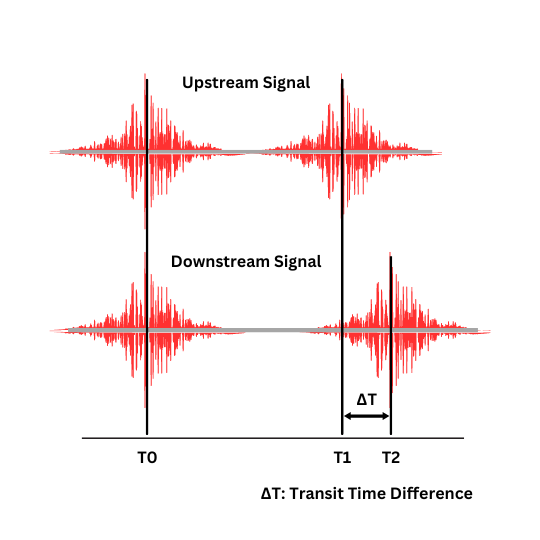

The Uf801 clamp-on water flow meter utilizes a sophisticated transit-time ultrasonic principle for precise velocity and volume flow rate determination. Its external installation on process pipes eliminates the need for internal instrumentation, ensuring a leak-free and non-invasive metering solution.

This advanced measurement technique provides high accuracy, repeatability, and reliability in water flow measurement, even in challenging conditions. The Uf801 clamp-on water flow meter is a valuable solution for any liquid flow measurement application.

The Uf801 clamp-on water flow meter employs the transit-time ultrasonic principle for precise flow measurement. Its external installation eliminates the need for internal instrumentation, pipe cutting, welding, flange installation, or hot-taps, setting it apart from traditional methods and ensuring a leak-free, non-intrusive solution. Learn more here.

The Uf 801-P provides high accuracy, repeatability, and reliability in water flow measurement, even in challenging conditions. Its versatility extends to various liquids, including water, chemicals, toxic media, or hydrocarbons, making it an ideal external flow meter for every industry.

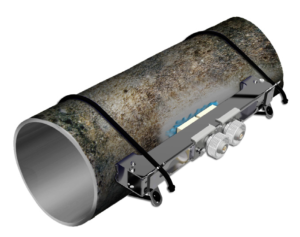

The Uf801 clamp-on water flow meter utilizes external installation on rusted water pipes so eliminating the need for in-line installation, pipe cutting, welding, flange installation, or hot-taps, ensuring a leak-free and completely non-invasive metering solution. The Uf 801-P has a wide pipe diameter range (10mm to 10,000mm) making is suitable for almost every site requirement.

The Uf 801-P excels in applications such as HVAC commissioning, flowmeter verification, energy audits, leak detection, and network metering. Usage limitations may apply in cases where liquids have a high concentration of suspended solids.

If the liquid that you are measuring contains entrained gas or suspended solids at or above a concentration of 10% (by volume) then you might want to consider using our Compu-Flow Doppler Ultrasonic Flow Meter for your flow measurements.

The Uf 801-P Clamp-on Water Flow Meter also serves as a valuable tool for flowmeter verification, as in-line flow meters (such as turbine or electromagnetic flowmeters) can suffer from calibration drift over time, causing measurement errors and negatively impacting process efficiency or final product quality. The Uf 801-P Clamp-on Water Flow Meter can be installed adjacent to existing flow meters for a quick accuracy check, helping to ensure the performance of flow meters is within specified accuracy.

Consider factors such as pipe material, pipe wall thickness, flow measurement range, pipe condition (rusted pipes etc.), straight pipe run, and any specific site requirements.

The Uf 801-P’s portability makes it suitable for various applications, including building energy auditing, network leak detection, and network metering, ensuring optimal performance for diverse requirements.

If you need help finding the right solution for your application, you may contact us and our engineers will be happy to help you.

You now have the option to rent our Uf 801-P portable ultrasonic flow meter to verify the accuracy of your flow meters. Or you may contact us for a meter verification service by an experienced engineer.

› Domestic water: Leakage detection, pump flow control, control of in-line flow meters, etc.

› Water (raw, waste): Pump flow control.

› Flow surveys: Troubleshooting installations, resolving disputes, etc.

› System Commissioning: Validation of system performance before handover of a project.

› HVAC: System balancing, thermal assessment (water for air conditioning and heating systems), etc.

› Hydrocarbons: Temporary flow measurement.

| Measuring Principle | Transit Time |

| Flow Channels | Single and Dual Channel |

| Accuracy | Up to ±0.5 % of reading |

| Repeatability | ±0.1% |

| Velocity Range | 0 to 30 m/s (0 to 98 ft/s) bi-directional |

| Minimum Operating Velocity | 0.03 ft/s |

| Pipe Diameter Range | DN10 to DN10,000 (0.5" to 390") |

| Pipe Material | Aluminium, asbestos, cast iron, copper, glass, grey cast iron, nylon, Plexiglas, polyethylene, PTFE, PVC, stainless-steel and steel. Other materials can be used if their physical properties are known. |

| Datalogger | Built-in datalogger records between 1 and 30 variables - up to 266,706 lines |

| Battery | Up to 14hr continuous use |

| Protection Rating | IP68 |

| Temperature Range | -10°C to 50°C (14°F - 122°F) |

› Light weight (less than 1kg)

› Easy to use

› IP68 ABS enclosure

› Multi-parameter data logger

› Stores up to 11 configurations/sites

› Timer/programmer

› Optional Input/output modules (analogue, digital)

› Graphic screen

› Echo, gain and quality index displayed

› Battery life up to two months, using timed operation

› Automatic zero calibration

› Ten flow calculations per second

› On every type of homogeneous liquid, even non-conductive

› On most types of gases – high and medium pressure*

› Non ideal flow conditions taken into account