The UF831 Clamp-On Flow and BTU Meter is suitable for accurately measuring and reporting Data Center Energy Consumption.

The UF 831 Flow & Energy Meter is a data center cooling meter that clamps on the pipe externally to measure data center energy consumption. The Ultraflux UF 831 data center flow meter guarantees reliable, accurate and stable results even in extreme measurement conditions.

The flow meter consists of a transmitter (the display) and a pair of ultrasonic sensors that are externally clamped on your chilled water pipes. This means no pipe cutting or welding is required to install this flow meter in your existing HVAC system. This reduces your installation costs as well as maintains your system’s structural integrity. Moreover, the flow meter has the lowest life-cycle maintenance costs that any other metering solution in the market.

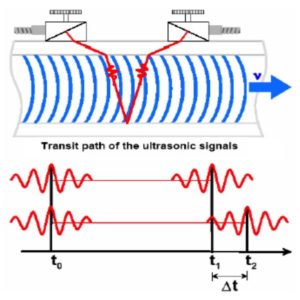

Operating Principle:

The Ultraflux UF 831 Flow Meter is based on transit-time technology that uses time-of-flight principle to calculate the flow velocity and volumetric flow rate. The flow meter consists of two transducers (or trans-receivers) that alternately send and receive ultrasonic signals to measure the transit time difference between the transmitted and received ultrasound signal. This difference in transit time is a direct measure of liquid flow rate. Learn more here.

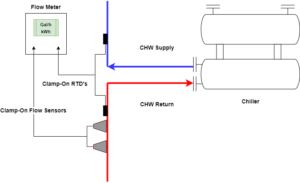

100% Clamp-On Solution:

The Ultraflux UF 831 is completely non-invasive i.e. no pipe cutting or any pipe modifications are required to install this energy metering system. The flow sensors as well as the temperature sensors (supply and return RTD’s) are clamped externally on the pipes for an easy and quick installation (see illustration below).

The Ultraflux UF 831 flow meter is capable of optionally measuring up to 8 water pipe lines simultaneously in your cooling or heating system (by additional sensors). This means you can monitor your main chilled water headers as well as any sub-branches that are suppling cooling energy to different parts or zones of your facility. Monitoring energy consumption across multiple areas or zones will give you a microscopic look at your energy consumptions that will allow you to optimize energy usage as well as implement energy efficiency strategies that will benefit you financially in the long run.

Other Typical Applications include:

› Aeraulic: Measuring air flow rate for test benches.

› Raw water and drinking water: Flow measurement and metering, process control, system supervision, etc.

› Climate engineering: Water metering (hot or cold) for air conditioning.

› Chemical products, even aggressive liquids: Process control, system management, etc.

› Food/farming products

› Crude oil: Management of samplers for controlling loading/unloading, etc.

› Refined oil products or liquefied gas (LPG): Regulation and control of transport system, etc.

› Energy: Calculation of the yield from hydroelectric power stations.

You now have the option to test out our ultrasonic clamp-on technology by renting or requesting an energy audit of your facility using our portable Uf 801-P ultrasonic flow meter.

Need help selecting the right product for your application? Contact us today!

| Technology | Ultrasonic Transit Time Clamp-On Flow Meter |

| Application | Liquid Flow & Energy Measurements (BTU/ kWh) |

| Pipe Size Range | DN10 to DN10,000 (external pipe dia) |

| Output Options | Modbus or others upon request |

| IP Rating | IP67/IP68 |

| Accuracy | 0.5% or better |

| Repeatability | 0.1% or better |

| No of Chords (pipes) | Single Chord (standard); Up to 8 Chords Possible (optional) |

| Operating Temperature Range | For use from -10°C to 50°C |

› Up to eight speed chords on a single pipe

› Up to 10 input/output modules (analogue, digital)

› Graphic screen

› Echo, gain and quality index displayed accurate

› Accurate up to 0.5%

› Repeatability up to 0.1%

› Automatic zero calibration

› Mathematical functions generator

› Multi-parameter data logger

› Field bus option: Modbus TCP/Modbus RTU