SONO-VARIO® sand moisture probe is an on-line sand moisture sensor suitable for sand and fine construction aggregates like gravel up to 5/32 inch (4mm).

SONO-VARIO® Sand Moisture Probe is perfect for measuring moisture in fine construction aggregates. Part of our SONO® sensors family, it works with sands, granite rock fines, stone, and gravel up to 4mm (5/32 inch) in size.

Our SONO VARIO – Xtrem® sensor is great for coarse aggregates like gravel, rock, crushed stone, and RAP up to 1.25 inches in size. Contact us to find the right sensor for your needs.

The SONO® sand moisture probe utilizes TRIME® TDR technology for precise and repeatable moisture measurements. Seztec’s sand moisture probes, with over 20 years of expertise, meet your aggregate and fresh concrete measurement requirements. Easily configure SONO® probes for applications like moisture measurement under a silo flap or clam gate, inside hoppers, or on a conveyor belt. Operating modes, such as single-value measurement and averaging, can be set directly inside the SONO® probe.

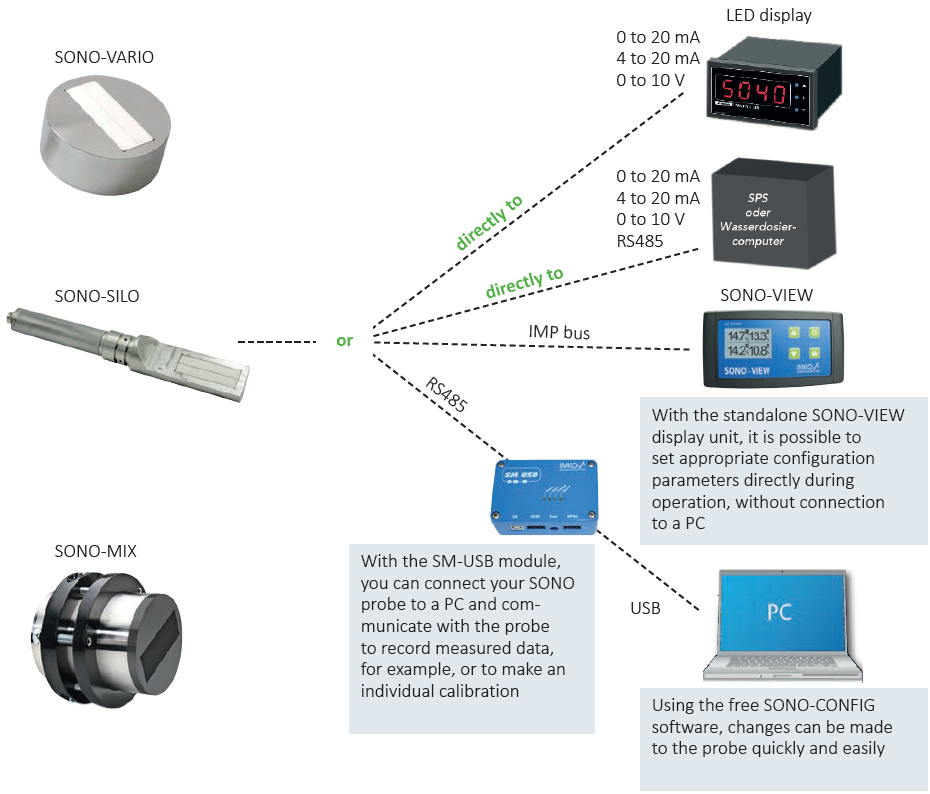

SONO sand moisture probes come with different industry standard outputs and communication protocols to meet various data transfer needs.

› Two analog outputs (0/4-20 mA) can send moisture content, electrical conductivity, and temperature directly to a PLC.

› You can import data via RS485 and IMKO’s own IMP-Bus interface.

› Connect to a local PC (USB port) using the SM-USB module or field display (SONO-VIEW).

› You can easily adjust individual measuring parameters and change material calibrations.

› Installation in containers, hoppers, above conveyor belts, or in silos.

› On-line installation including below a clam-gate, and on a weigh-belt.

› Quarries and mines

› Concrete mixing plants (ready mix and pre-cast)

› Bitumen industry

› Foundry return sand, clayey soils, and clay

› Moisture measurement in various minerals like quartz sand, coal, iron oxide, fly ash, lime, pozzolan grains.

› Easy to install and replace

› User friendly interface for quick commissioning and programming

› Intelligent sensor diagnostics for troubleshooting

› Networked sensors (multiple sensors in a bus configuration for SCADA)

› 15 standard linear calibrations for various material types, pre-programmed in the sensor

› Long service life and low maintenance

› Replaceable sensor head

If you are looking for a portable device to measure moisture content in sand, gravel, rock, crushed stone, and other aggregates etc. directly on the field, then check out our HD2® Portable Aggregate Moisture Meter.

| Sensor casing | High Grade Steel V2A 1.4301 |

| Probe head surface | Stainless steel with abrasion-resistant aluminium oxide ceramic |

| Moisture measurement range | The sensor measures from 0% up to the point of material saturation |

| Conductivity measurement range | 0…10dS/m |

| Temperature measurement range | 0°C …70°C (32°F...158°F) |

| Power supply | +7V to max. +24V DC 1.5 W max. |

| Signal output | 2 x Analog outputs 0(4)…20mA |

| Communication | RS485 interface, IMP-Bus, Other options possible on request |

| Field display | SONO-View field display optionally available |

› Highly reliable when measuring complex materials like minerals, powders, granules, quartz sand, food and sludge

› Thanks to TRIME technology it is unaffected by steam or changing particle sizes of sand and gravel

› The additionally measured radar-based conductance up to 12dS/m allows conclusions on other parameters of the material recipe

› Simple installation in containers, shafts, silos and conveyor belts

› Probe head made of stainless steel with rectangular ceramic window

› In case of abrasion at probe head an automatic correction of the measuring value happens – without re-calibration