Thermal mass flow meters are used for direct mass measurement of fluids (gases or liquids) flowing through a pipe. Unlike volumetric flow meters such as turbine, variable area, etc., thermal mass flow meters are not affected by temperature or pressure of the fluid being measured.

Thermal mass flow meters are based on King’s Law that introduces the relationship between rate of heat absorption in a flowing medium to its mass flow velocity.

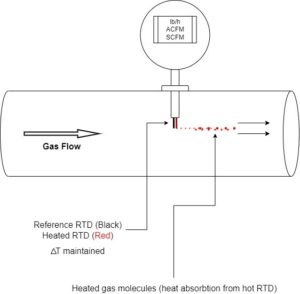

The sensing probe in thermal mass flow meters consists of two temperature sensors (see diagram below), one of which measures the process temperature (Black RTD), and the other is an electrically heated sensor (Red RTD) that disperses heat energy to the flowing fluid molecules through heat convection. A pre-determined temperature difference, ∆T, between both sensors is maintained by the flow computer by constantly supplying electrical voltage to the heated sensor. The rate of flow of fluid is directly proportional to the electrical energy supplied to the heated sensor. The electrical signal is scaled and converted to mass flow signal by the flow computer.

Our thermal mass flow meters are offered in various configurations including insertion and in-line – see below.

Insertion flow probes are suitable for applications where pipe cutting or installing flanges is not desired or forbidden. Therefore, a process connection is made in the pipe via hot tapping or cold tapping to install proper connection fittings for the insertion flow probe.

The second meter type is the flanged with in-line flow body and is suitable for new installations where process shutdown is possible. The operating principles, construction, and applications of both flow meter configurations are identical. Whereas the factors that will affect the performance of these meters is the process conditions, installation conditions, and meter sizing.

› Measurement of mass flow, direct output of standard volume flow, without additional measurement of pressure and temperature

› No moving parts, therefore low maintenance

› Highly accurate than volumetric flow meters

› Low pressure loss due to minor obstruction to flow

› ATEX or DVGW certification available, thus recommended for gases such as natural gas, hydrogen, biogas, etc.

› Highly accurate at small as well as large flow rates

› Pressure and temperature compensated by the thermal mass flow principle

› Easy installation and removal of the sensor from the measuring section

Not sure which flow meter is right for your specific application? Then contact us today and we will be happy to help you find the right instrument for your measuring task.