A successful case of flow measurement on asbestos cement pipe using Ultraflux Uf801P non-contact water flow meter.

As early as the 1930’s, asbestos cement (AC) pipe had been widely used by cities and municipalities to transport domestic water to households and commercial buildings all around the United States. It was used because of its light weight, low coefficient of friction, and resistance to corrosion. After discovery of associated health risks with asbestos in drinking water, new installation of AC pipes has long been ended, but thousands of miles of existing AC water pipes are still beneath our streets that have never been replaced. These pipe networks still need to be monitored for water consumption and water leaks and municipalities have long relied on in-line/flanged water meters for this purpose. AC Pipes have significantly higher break rates since these pipes are nearing their life cycle; therefore, they cause undetected underground leaks resulting in hefty water loss annually.

image credit: www.osha.oregon.gov

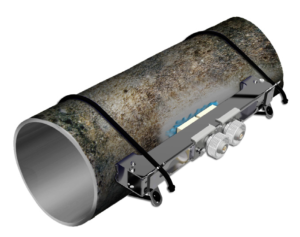

Because of the deterioration seen in AC pipes, it can become very tricky to install new water flow meters in the water network as pipe cutting can cause leaks or serious pipe damage that can cost thousands of dollars in repairs. To avoid this problem we offer our “non-contact ultrasonic flow meters” to accurately monitor water consumption, and detect leaks in real-time without cutting into the pipes.

Our non-contact ultrasonic flow meters are mounted externally on the AC pipe and require no mechanical works like pipe cutting, flange installation, and drilling. Thus ensuring that pipe integrity is conserved and losses are minimized.

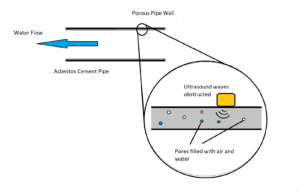

One major problem with measuring water flow on AC pipes is the deterioration of the pipe walls that causes air and water pores within the pipe walls that interfere with signal transmission of a non-contact ultrasonic water flow meter. Therefore, specialized sensors with enough signal penetration power are needed to make successful non-contact measurements on these “porous” pipes. Not all non-contact water flow meters in the market are capable of being successful on AC pipes. Seztec is one of the very few industry leaders that offers custom sensors with extremely low frequencies (high penetration power) that make flow measurement even on AC pipes possible.

Below is a great example of a successful water flow test using our Uf801P non-contact water flow meter (portable flow meter) on a DN300 asbestos cement pipe. We used an ultra-low frequency sensor to achieve stable and accurate flow measurements on several underground pipes for a water district in the US. The measured flow readings were cross-referenced with an existing in-line electromagnetic flow meter and results were within ±0.08%. Our clamp-on ultrasonic sensors are capable of measuring flow on a wide range of pipe diameters (1/2″ to 400″) which makes this instrument a very practical portable tool for all your water monitoring and leak detection needs.

The grease stains as seen below on the pipe indicate that other brands conducted field tests on this location as well, but non of their ultrasonic sensors had enough penetrating power to transmit ultrasound signal through the porous wall and back to achieve usable flow data.

We offer permanent as well as portable non-contact ultrasonic water flow meters. Please contact us with your flow application and our engineers will be very happy to work with you to find a solution!

Originally published Jan 8, 2021 5:30:00 PM, updated April 01 2022 Copyright © 2022 Seztec LLC

Related Products: