Should you buy an Ultrasonic Clamp-On Flowmeter or a Magnetic Flowmeter? Well, the answer is not that straight forward. When it comes to selecting metering equipment for your process you cannot follow “one size fits all” approach. Meter selection requires a little bit of technical analysis and objective thinking, so having deep understanding about your application requirements will come in handy and help you arrive at the right answer quickly. An incorrect metering instrument for your liquid or gas application can mean thousands of dollars of annual losses resulting from process/plant inefficiency, incorrect flow data, and replacement costs.

To get started, first lets take a quick look at the measuring principles of both metering technologies to get a better hold on the basics.

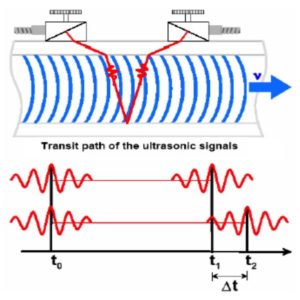

Ultrasonic Measuring Principle:

The ultrasonic clamp-on flow meter utilizes transit-time ultrasonic technology (time of flight) to calculate the flow velocity and volumetric flow rate of the liquid. The flow meter consists of two transducers or trans-receivers that alternately send and receive ultrasonic signals to measure the transit time difference between the transmitted and received ultrasound signal. This difference in transit time is a direct measure of liquid flow rate.

Key benefits of ultrasonic technology:

› 100% non-contact flow measurement (no liquid contact)

› Zero pressure drop created

› No moving parts and no wear and tear of flow transducers – long service life (+10 years)

› No re-calibration required – zero measurement drift

› No risk of pipe leaks – sensors installed externally on the pipe

› Suitable for a wide pipe size range – adaptable to future plant upgrades or pipe replacements

› Modular design – easy sensor and transmitter replacement requiring no system shutdown

› Low installation costs and ownership costs compared to in-line meters

› Accurate and repeatable: normally ±1..3% (±0.5..1% possible with advanced calibration)

› Easy installation and virtually zero maintenance costs

› Can measure conductive or non-conductive liquids

› Independent of liquid temperature, pressure, chemical properties, and viscosity.

Limitations of ultrasonic flow meters:

› Transit-time technology is affected by concentration levels of suspended solids and aeration in the liquid (maximum allowable concentration 5%…10%). Will require a doppler technology to measure liquids with fluctuating or higher solid contents (+10%).

› Not suitable for process control such as batching or chemical injection (slow response time as compared to mechanical meters i.e. turbine or gear meter)

› Highly affected by pipe condition (internal or external pipe rust, uneven surface etc.)

› Not as accurate as in-line meters such as magnetic, Coriolis or turbine meters: normally ±1..3% standard accuracy (±0.5..1% accuracy possible with advanced calibration at extra cost)

› Accuracy highly affected by incorrect pipe dimensions programmed into the meter

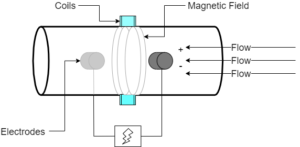

Electromagnetic Measuring Principle:

The operating principle of electro-magnetic flow meters is based on Faraday’s Law of Magnetic Induction. This means when an electrically conductive liquid (water-based liquids) flows through the magnetic flux created by the magnetic coils of the flow meter, a voltage is induced across the two electrodes. This induced voltage can be mathematically correlated to the flow velocity of the fluid. The voltage signal is carried to the transmitter to obtain accurate liquid flow readings.

Key benefits of electromagnetic technology:

› Much higher accuracy than clamp-on ultrasonic flow meters (±0.1..0.5%)

› Suitable for process control as well as process monitoring applications

› Reliable and field tested technology around the world

› Negligible pressure drop created

› Wide variety of electrode and liner materials to suit a wide variety of applications

› No moving wetted parts – no wear and tear

› Unaffected by suspended solids in the liquid

Limitations of magnetic flow meters:

› Can measure only conductive liquids (5-20μS or higher, e.g. water-based liquids)

› Sensor electrodes prone to internal deposit formation – causes measurement drift in the long run

› Liner materials prone to wear and tear after extended use

› High installation and replacement costs

› Requires proper grounding as flow signals are affected by electrical noise.

› Not as accurate at low-flow velocities.

› Accuracy affected by liquid aeration

› Complicated installation and commissioning procedures

Conclusion:

Every flow measurement application requires proper meter selection to avoid meter failures and process inefficiencies. When designing a measurement station it is important to understand the product to be measured, install the correct equipment, and implement the appropriate correction calculations or factors. The following considerations need to be addressed to minimize measurement uncertainty and monetary losses: What is the composition or fluid to be measured? What is the minimum, maximum and normal operating conditions? How does the operating pressure and temperature affect the fluid? What other operational factors affect proper measurement? Based on the answers to the previous questions, what is the best measuring device to handle the product?

If you have a difficult flow measurement application our experienced engineers would be happy to work with you and help you select the right device for your requirement. Visit our website www.seztec.com to explore our product range or email us at sales@seztec.com with your measurement problem.

Originally published Dec 12, 2021 2:00:00 PM, updated Mar 14 2022 Copyright © 2022 Seztec LLC

Related Products: