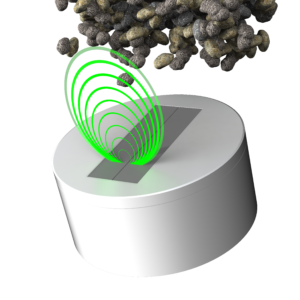

Introducing our SONO® Standard Conveyor Moisture Meter for sand and aggregates, providing reliable on-line moisture measurements for seamless process control.

Introducing our SONO-VARIO® Conveyor Moisture Meter for sand and aggregate applications, a pivotal member of our SONO® sensor range, delivering real-time moisture measurements on conveyor belts and beneath silos.

Accurate real-time monitoring of moisture levels in sand and aggregates is essential for optimizing operations in the construction in concrete production. Our specialized SONO-VARIO® Conveyor Moisture Meter is designed to precisely measure moisture content in various types of sand and construction aggregates used in concrete production, empowering users with complete control over product quality.

At the core of our sensor technology lies the revolutionary TRIME® TDR Technology. This patented innovation enables direct mounting onto conveyor lines, ensuring continuous penetration into the material for highly accurate and consistent moisture readings of 0.1% or better.

With over two decades of expertise, Seztec’s moisture probes are the trusted choice for sand and aggregate moisture measurement needs, providing efficiency gains and cost savings in your operations.

The innovative feature of SONO-VARIO’s sensor head replacement offers significant cost savings and reduces downtime. Instead of replacing the entire unit, users can simply replace the sensor head when necessary, minimizing maintenance costs and ensuring continuous operation without prolonged downtime.

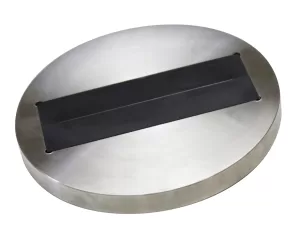

The supplied mounting plate assembly facilitates quick and straightforward installation of SONO-VARIO® Conveyor Moisture Meter directly onto conveyor belts, eliminating the need for complex setup procedures. This plug-and-play design minimizes installation time and ensures hassle-free integration into existing conveyor systems.

Choose from 15 pre-programmed standard linear calibrations, allowing you to select the ideal setting for various sand and aggregate types, perfectly aligning with your sand moisture measurement requirements.

For highly abrasive aggregates such as gravel, rock, crushed stone and RAP (Reclaimed Asphalt Pavement), up to 1-1/4 inch, our SONO VARIO – Xtrem Aggregate Moisture Sensor will be suitable. Contact us to find the right sensor for your application.

| Measured Parameters | Moisture Content %, Temperature, Conductivity |

| Technology | TDR (Time Domain Reflectometry) |

| Sensor Body | Casing: High Grade Steel V2A 1.4301 |

| Sensor Head | The probe head surface consists of stainless steel with abrasion-resistant aluminium oxide ceramic. |

| Moisture Measurement Range | The sensor measures from 0% up to the point of material saturation. Measurement ranges up to 100% moisture (pure water) are possible with a special calibration. |

| Conductivity Measurement Range | The sensor, as a material-specific characteristic value, delivers the radar-based conductance (ECTRIME) in a range of 0…12dS/m. |

| Temperature Measurement Range | Measurement range: 0°C …70°C (150°C on request). |

| Accuracy | Better than 0.1% for most applications. |

| Analog Outputs | 2 x Analogue Outputs 0(4)…20mA |

| Factory Calibrated | The sensor is provided with a universal calibration for sand. A maximum of 15 different calibrations can be stored. |

| Power Supply | +12V to max. +24V-DC, 3W |

Key Advantages

› Exchangeable sensor head with wear-resistant steel/ceramic window.

› Auto-correction function: the probe recalibrates itself in the event of abrasion at the probe head.

› Up to 15 different material calibration curves are directly stored inside the probe.

› Intelligent pre-processing inside the probe with smooth mean value accumulation and powerful adjustable filters.