The C6™ Ultrasonic Doppler Flow Meter is a non-invasive flow meter to measure flow of dirty or aerated liquids with suspended solids.

The C6™ ultrasonic doppler flow meter is a non-contact portable flow meter suitable for liquids with high concentration of suspended solids or aeration. The C6 doppler flow meter is perfect for sewage sludge, slurries, aerated liquids, raw sewage, dredges, pulp, plastics, and wastewater.

When you need a reliable portable ultrasonic doppler flow meter, the C6™ is the right choice. This flow meter has been tested in the field for the last 30 years. The Compu-Flow™ Doppler ultrasonic flow meter provides an accurate and easy-to-use measuring system for high-solid fluid flow through pipes with inside diameters ranging from 0.50 inches to 999 inches.

If you are in need of a permanent or fixed Doppler flow meter, please check our our C6 permanent flow meter here.

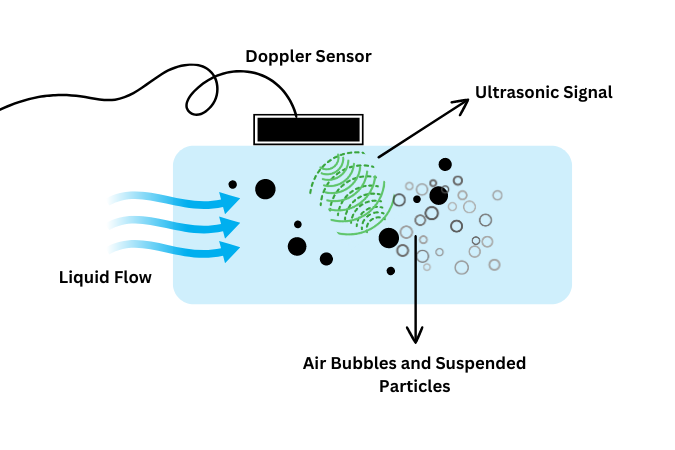

The Doppler principle, discovered by Christian Doppler in 1842, explains the change in frequency or wavelength of a wave in relation to an observer moving relative to the wave source. In Doppler flow meters, the principle is used to measure the velocity of a fluid within a pipe. Here’s a simplified explanation:

1. An ultrasonic transducer emits waves into the fluid.

2. These waves reflect off particles or bubbles in the fluid.

3. The reflected waves return to the transducer with a frequency shift.

4. The device analyzes this shift to calculate fluid velocity.

5. Combined with the cross-sectional area of the pipe, the flow rate is determined.

› Municipal Sludge’s & Wastes

› Oils

› Paper Pulp

› Product Processing

› Plastics

› Rendering Products

› Reservoirs

› Rivers and Streams

› Runoffs

› Sludge’s

› Slurries & Tailings Dams

› Suspended Solids

› Tars

› Most liquids containing suspended particles or air bubbles

| Measuring Principle | Doppler Effect |

| Flow Range | 0-50 fps |

| Pipe Diameter Range | 0-999 inches |

| Memory | Stores all parameter records |

| Transducer Cable Extention | upto 5000ft |

| Transducer Protection Rating | IP68 |

| Signal Outputs | Pulse, Analog (4-20mA), Limit Alarms, Batch Control |

› Field Ready, Quick Setup, User Friendly

› No pipe section or spool piece is required to install the meter.

› The meter is not affected by changes in temperature, viscosity, specific gravity, or the speed of sound within the liquid.

› The liquid does not have to be electronically conductive.

› Wide range of temperature applications: -30 to 90 deg C – up to 250 deg C with special fittings.

› AC or DC operation, solar or battery power.

› Non- invasive, Submersible, Clamp-on transducers

› Signal cable lengths up to 1500 m ( 5000 ft)

› High accuracy even in turbulent flows

› Wide pipe diameter range 13mm (0.50 inches) – 9999 mm (999 inches)

› All pipe materials Including – PVC, HDPE, Plastic, Steel & Stainless Steel, Iron, Rubber, Concrete, and Copper