SONO-VARIO Xtrem® on-line aggregate moisture probe is suitable for coarse aggregates like granite, gravel, rock, crushed stone and RAP, up to 1.25 inch.

SONO VARIO Xtrem® Aggregate Moisture Probe is suitable for highly abrasive and coarse aggregates like granite, recycle, gravel, rock, crushed stone and RAP, up to 1-1/4 inch diameter.

Our SONO aggregate moisture probe utilizes patented TRIME® TDR technology whose measuring field penetrates deep into a large volume of material, resulting in highly accurate and repeatable moisture measurement values. Seztec’s moisture probes and over 20-years of expertise meet all your aggregate and fresh concrete measurement needs.

The Xtrem® aggregate moisture probe is custom designed to offer reliable, repeatable, and accurate moisture measurement readings (better than 0.1%) in concrete and asphalt production applications. The sensor head is constructed out of high quality ceramic to endure high abrasion. And underneath its packed with feature-filled intelligent electronics with advanced algorithms and filters to automatically calibrate and adapt to such surface abrasion.

In extreme cases where the sensor head is damaged from abrasion we offer customers the flexibility to replace the sensor head without having to replace the whole probe, an option that other competitors do not offer. This increases your maintenance intervals and saves you time and money.

Furthermore, the probe is equipped with a built-in temperature sensor that is placed just a few millimeters beneath the sensing head to provide real-time material temperature readings as well as to carry out automatic temperature compensation to control measurement drift and offer highest industry accuracy.

Lastly, 15 standard material calibrations are pre-programmed in the sensor that allow you to select from a range of material types to meet all your measurement needs.

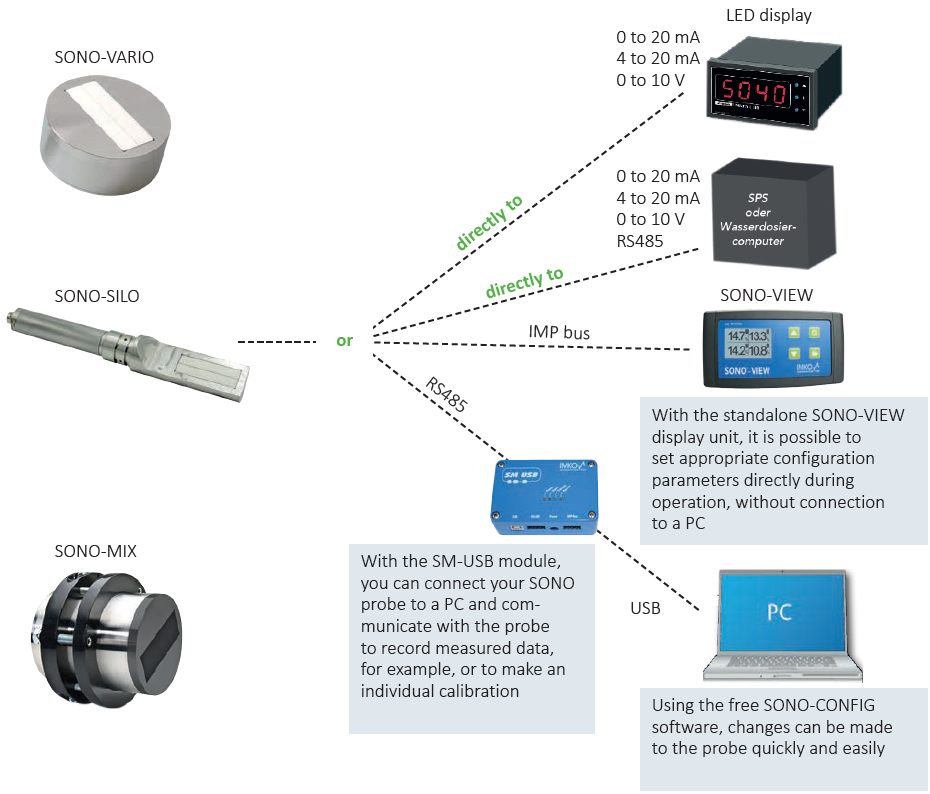

All SONO aggregate moisture probes are offered with a variety of standard industry outputs and communication protocols to meet every data transfer need. The measured parameters such as moisture content, the conductivity, and temperature, can either be transferred directly into a PLC via two analogue outputs 0(4)…20 mA or imported via an RS485 and IMP-Bus interface. In addition, SONO-probes can be directly connected to a local PC (USB port) via the SM-USB module or the field display – SONO-VIEW. This allows the customer to also adjust individual measuring parameters or conduct calibrations.

› On-line process moisture measurement

› Concrete and asphalt production

› Ready-mix and pre-cast

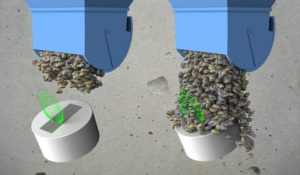

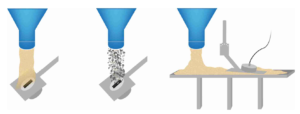

› Installation under a clam-gate

› Installation on conveyor belt, feeder belt, weight belt, hopper,

screw conveyor and others.

› Also suitable for highly conductive materials like Foundry Sand, Ore, Slag, and Coal

› Exchangeable sensor head with wear-resistant steel/ceramic window.

› Auto-correction function: the probe recalibrates itself in the event of abrasion at the probe head.

› Up to 15 different material calibration curves are directly stored inside the probe.

› Intelligent pre-processing inside the probe with smooth mean value accumulation and powerful adjustable filters.

| Sensor casing | High grade steel V2A 1.4301 |

| Sensor head | Hardened steel with abrasion-resistant special ceramic. |

| Moisture measurement range | The sensor measures from 0% up to the point of material saturation |

| Conductivity measurement range | 0…10dS/m |

| Temperature measurement range | 0°C …70°C (32°F...158°F) |

| Power supply | +7V to max. +24V DC 1.5 W max. |

| Signal output | 2 x Analog outputs 0(4)…20mA |

| Communication | RS485 interface. Other options possible on request |

| Field display | SONO-View field display optionally available |

› Highly abrasion-resistant

› Precise measurement even under extreme conditions

› Reliability even with steam or varying sizes of sand and gravel

› Simple installation in containers, shafts, silos and at conveyor belts

› Automatic correction of measuring value in case of abrasion of the probe head without re-calibration

› Floating averaging, adjustable filter and up to 15 calibration curves

› A RS485 interface for SCADA integration

› A data bus protocol to connect several SONO probes

› Various communication options like Profibus, Ethernet and more