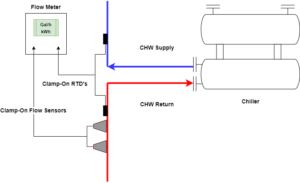

The Minisonic HVAC Flow Meter is used to monitor supply and return water flow, and heating or cooling energy (BTU).

The Minisonic HVAC Flow Meter or Chiller Flow Meter can be used for multiple measurements that need to be taken within heating or cooling HVAC systems, including supply and return water flow, supply and return temperature, and heating or cooling energy consumed (BTU).

The Minisonic flow meter is a great solution for BTU metering, and cost allocation or sub-metering settings. Because of its large pipe diameter range (up to DN 10,000) it can be used at various points in the HVAC system including: chiller individual supply headers, condenser lines, main chilled water (CHW) headers, supply or return CHW or hot water lines, boilers, and heat exchangers.

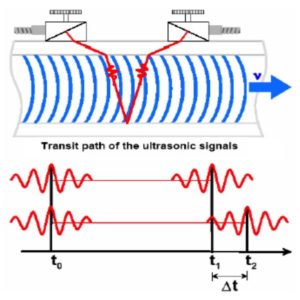

Measuring Principle:

The Minisonic HVAC Flow Meter is based on transit-time technology that uses time-of-flight principle to calculate the flow velocity and volumetric flow rate. The flow meter consists of two transducers (or trans-receivers) that alternately send and receive ultrasonic signals to measure the transit time difference between the transmitted and received ultrasound signal. This difference in transit time is a direct measure of liquid flow rate. Learn more here.

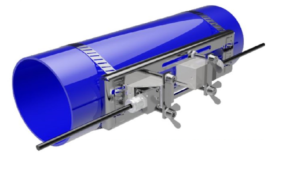

100% Clamp-On Solution:

The Minisonic Flow Meter is completely non-invasive i.e. no pipe cutting or any pipe modifications are required to install this metering system. The flow sensors as well as the temperature sensors (supply and return RTD’s for measurement of energy consumption or BTU) are clamped externally on the pipes for an easy and quick installation (see illustration below).

HVAC Challenges:

Heating or cooling systems in a building are prone to several mechanical and hydraulic issues that affect the energy generation and overall efficiency of the HVAC system. These problems, if remained unmonitored, can result in thousands of dollars in monetary losses every year.

(1) Pumping and Insufficient Water Flow Issues

A major inefficiency in a cooling or heating system is related to water flow issues in the system. Over time, pumps suffer from internal wear and tear that reduces their overall efficiency and affects their ability to provide specified water flow to the system (gpm). Insufficient water flow through the system may cause severe damage to the chillers and may also cause the pipes to freeze. Therefore accurately monitoring pump flow and chiller flow is extremely critical to the well-being of your HVAC system.

(2) Hydraulic Balancing

Water cooled chillers reject absorbed heating through an additional water loop called condenser water lines that feed heated water to the cooling towers for cooling. Normally, a building may have more than one cooling towers to meet the energy demand of the building. For maximum cooling efficiency, operator must ensure that equal amount of water flows through every cooling tower/cell. The Minisonic HVAC Flow Meter can be installed on condenser pumps to accurately measure condenser water flow reaching the cooling towers. This information can help the operator to optimize their pump flow for maximum cooling efficiency.

We offer flow meter rental service so you can carry out pump flow verification, flow meter verification, and hydraulic balancing at your cooling plant. Our rental solutions are 100% non-intrusive, meaning no pipe cutting needed to make measurements.

Here is an interesting case study about hydraulic balancing where we helped a cooling plant optimize their condenser water flow.

(3) Energy Loss at Low Water Flow Rates

At times of low-demand the building may consume much lower cooling or heating energy. Accurately measuring such low flow rates is crucial as energy transfer at low water flow rates normally go unmetered which is practically giving away “free energy”. The Minisonic HVAC Flow Meter can measure extremely low flow velocities (0.03 ft/s) to provide maximum ROI to energy producers as no energy goes unmetered.

(4) Maintenance Costs

A major operating cost of a cooling or heating system is the maintenance cost. This includes pump overhaul, chiller overhaul, insulation costs, flow meter or BTU meter re-calibration and replacements, water leaks, water treatment, etc. The Minisonic HVAC Flow Meter is a 100% clamp-on solution and does not require any pipe cutting for installation, removals, or replacements. The Minisonic flow meter can be retrofitted at any location in your HVAC system and can be moved to a different location in the future without system shutdown. Since the flow sensors are strapped onto the pipe externally, they do not come in contact with the liquid, so you can be assured that the flow meter will not require any maintenance or re-calibration during its life span. Furthermore, we offer a unique permanent ultrasound coupling pads (elastomer pads) to replace the conventional ultrasound gel that gets washed away because of pipe condensation on CHW pipes. Our permanent coupling pads eliminate the need for periodic flow meter maintenance to re-apply ultrasound gel, thus keeping your maintenance and operating costs low.

(5) Network Water Leaks

Chilled water systems, especially in district energy plants, are connected to a vast network of underground insulated water pipes that stretch out for miles. These lines are normally unmetered and any network leaks go undetected. Using our Minisonic non-intrusive flow meter the operators can retrofit any number of metering points in the network to monitor supply and return water flows in the main headers and individual branches to monitor water leaks.

Related Products:

| Technology | Transit time ultrasonic flowmeter |

| Signal Treatment | Analog + ESC (Echo Shape Control) |

| Measured Values | Volumetric flowrate, Velocity, Speed of sound, Totalizers, Signal quality, Gain, Transit time |

| Standard Outputs | (1x) isolated 4-20 mA output, (2x) isolated contact output |

| Optional I/O | (4x) 2 wires Pt100 input, (2x) 3 wires Pt100 input |

| Display | Clear OLED Graphic display 128x64 pixels |

| Communication | Modbus TCP through Ethernet, USB port for update and logger downloading, Modbus RTU through RS 232 / 485 |

| Power Supply | AC 110 – 230 V 50/60 Hz or DC 12 - 24 V |

| Enclosure | Aluminium housing, robust and compact |

| Protection | EN/IEC 60659 IP67 |

› Local Visual Display Indication

› Does not require pipe cutting or system intrusion for installation (no need for frequent maintenance in remote areas)

› Suitable for difficult flow conditions (pulsating flow, turbulent flows) with quick response time and high measurement frequency (10 flow calculations/second).

› Performs accurate flow measurements of cold water and hot water

› Low-risk measurement system – no hazardous pipe leaks

› Suitable for wide variety of pipe materials, large pipe diameter range, and unaffected by pipe wall thickness, viscosity, and fluid pressure or temperature

› Offers high turn down ratio and detects very low flow velocity (+/-0.03ft/s)

› Lower cost of ownership as compared to insertion/in-line flow meters

› Every flow meter is factory calibrated (traceable to national standards) and delivered with a calibration certificate

› Patented quick-mounting pipe fixtures and permanent coupling compound allow for easy and air tight sensor installation in tight spaces with no need for maintenance.

› Bidirectional flow measurement (forward and backward)

› Modular design with various inputs/outputs to offer flexible communication options