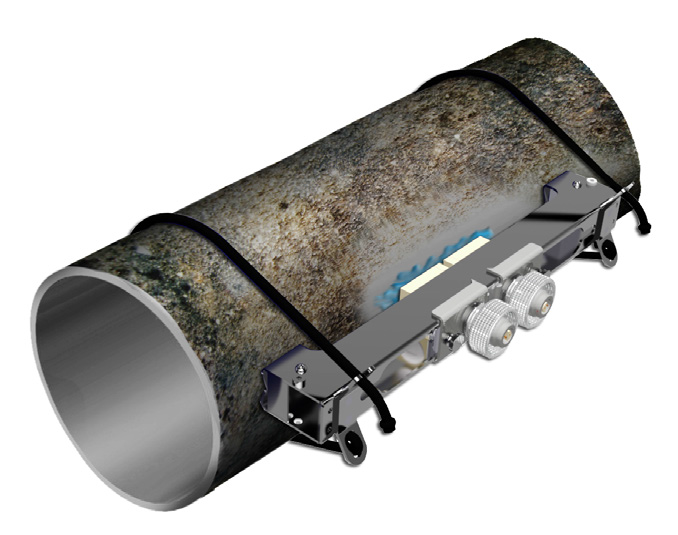

The Ultraflux Uf 811 ultrasonic flow meter is a high-performing “clamp-on” solution for permanent liquid flow applications.

The Ultraflux Uf 811 Clamp-on Ultrasonic Flow Meter is a non-intrusive flow meter that uses transit-time ultrasonic technology to calculate flow velocity and volumetric flow rate.

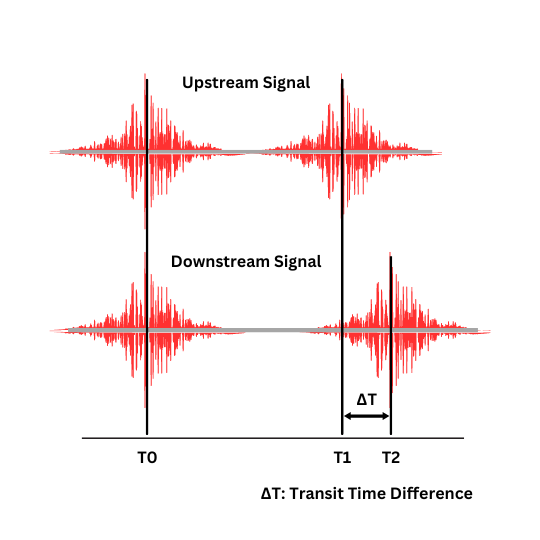

This ultrasonic flow meter uses two transducers to alternately send and receive ultrasonic signals, which measures the transit time difference between the transmitted and received signals, directly determining the liquid flow rate.

The Uf 811 ultrasonic flow meter has a wide range of pipe diameter compatibility, from 10mm to 10,000mm, making it a cost-effective replacement for existing in-line or insertion flow meters that are expensive to repair or replace. Additionally, the ultrasonic flow meter is capable of measuring all conductive and non-conductive liquids including domestic water, waste water, chemicals, demineralized and purified water, hydrocarbons, and any other transparent liquids.

The Uf 811 Ultrasonic Flow Meter uses advanced transit-time ultrasonic technology to calculate flow velocity and volumetric flow rate. It is sensitive to high and low flow velocities, ensuring accurate and reliable results even in extreme conditions. The ultrasonic flow meter is equipped with a user-friendly interface and can be easily programmed and configured via USB port. Learn more here.

The UF 811 ultrasonic flow meter uses advanced digital signal processing to offer a wide dynamic measuring range and is sensitive to high as well as low flow velocities. This guarantees accurate, stable and reliable results even in extreme measurement conditions.

With advanced digital signal processing, the Uf 811 ultrasonic flow meter offers a wide dynamic measuring range and is sensitive to high and low flow velocities, ensuring accurate, stable, and reliable results in extreme measurement conditions. Furthermore, it is an ideal solution for water leak detection in pipe networks in utilities and chilled water systems, as it can detect liquid velocities down to ±0.03 ft/s.

As a non-invasive flow meter, the Uf 811 requires no pipe cutting, welding, or shutting down of processes or systems, making it a practical solution for retrofit installations on existing pipe networks. It also reduces the installation costs to a minimum and overall cost of ownership of the flow meter. Learn more here.

With all industry standard communication protocols such as serial link RS232 or RS485 to JBUS/MODBUS, the Uf 811 offers bidirectional field communication and real-time diagnostics. The ultrasonic flow meter is user-friendly with a simple interface and easy commissioning process that can be programmed and configured via USB port. On-screen signal visualization and diagnostics provide troubleshooting capabilities on-site.

› Domestic water: Flow measurement and metering in treatment station works, network flow measurement, etc.

› Waste water: Flow measurement at pumping stations, in systems, inlets in treatment works, effluent etc.

› Raw water: Flow measurement in fire mains, system monitoring, etc.

› HVAC: Energy assessment, hydraulic modeling, leak detection.

› Chemical products: Flow measurement for all products, even aggressive chemicals (such as chlorides and acids, etc.).

› Pharmaceutical sector: Ultrapure water flows, purified water system processes, etc.

› Automotive, food and farming, energy, etc.

You now have the option to test out our ultrasonic clamp-on technology by renting or requesting a FREE product demo of our portable Uf 801-P ultrasonic flow meter before you decide to make the investment.

| Technology | Ultrasonic Transit-Time |

| Measuring Media | Liquids & Gases |

| Accuracy | ±0.5% of reading |

| Repatabiltiy | ±0.1% |

| Pipe Materials | Wide range of metallic and non-metallic pipe materials |

| Pipe Diameter Range | DN10 to DN10,000 (0.5" to 393") |

| Velocity Range | 0 to 30 m/s (0 to 98 ft/s) bi-directional |

| Minimum Operating Velocity | 0.03 ft/s |

| Display | Graphical LCD screen (14 lines x 20 characters) |

| Datalogging | Multi-Parameter logging up to 536,886 data points |

| Troubleshooting | On-Screen Oscilloscope |

| Communication | Serial link RS232 or RS485 to JBUS/MODBUS protocol • 115,200 Bauds - USB port |

| Ingress Protection | IP68 |

| Operating Temperature | -20°C to 70°C (4°F - 158°F) |

| Power Supply | 10-32V DC |

› Local Visual Display Indication

› Does not require pipe cutting or system intrusion for installation (no need for frequent maintenance in remote areas)

› Suitable for difficult flow conditions (pulsating flow, turbulent flows) with quick response time and high measurement frequency (10 flow calculations/second).

› Performs accurate flow measurements of slurries or liquids with suspended solids or aeration (less than 5-10% of total volume)

› Low-risk measurement system – causes no leaks in the system

› Does not depend on pipe material, pipe diameter, pipe wall thickness, viscosity, and fluid pressure or temperature

› Offers high turn down ratio and detects very low flow velocity (+/-0.03ft/s)

› Lower cost of ownership as compared to insertion/in-line flow meters

› Every flow meter is factory calibrated (traceable to national standards) and delivered with a calibration certificate

› Matched transducers, integrated temperature compensation and advanced digital signal processing guarantee a high zero point stability and drift free measurement readings

› Patented quick-mounting pipe fixtures allow for easy and air tight sensor installation in tight spaces with no need for maintenance.

› Bidirectional flow measurement (forward and backward)

› Modular design to offer single chord (single flow channel) or dual chord (dual flow channel e.g. supply and return) configurations.