Uf 801-P clamp-on flowmeter is used for temporary liquid flow & thermal energy measurements.

The Ultraflux Uf 801-P Portable Ultrasonic Clamp-On Flow Meter is your reliable solution for liquid flow measurements. The Uf 801 is suitable for all conductive and non-conductive liquids such as water, chemicals, toxic media, hydrocarbons etc. The installation does not cause any leaks in the system because the flow meter uses clamp-on sensors, therefore the installation does not require any pipe cutting.

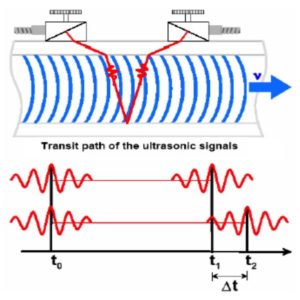

The Uf 801-P clamp-on ultrasonic flow meter is based on transit-time technology that uses time-of-flight principle to calculate the flow velocity and volumetric flow rate. The flow meter consists of two transducers (or trans-receivers) that alternately send and receive ultrasonic signals to measure the transit time difference between the transmitted and received ultrasound signal. This difference in transit time is a direct measure of liquid flow rate. Learn more here.

This instrument is designed for use by plant managers and maintenance technicians with a very user-friendly interface to allow anyone to use it with ease without any extensive training or technical knowledge. You can carry out various maintenance activities using this portable flow meter such as:

HVAC Commissioning (water-based systems): All HVAC systems (heating and cooling systems) require several checks during commissioning stage before the project is approved and handed over to the client. Our portable flow meter can help with primary and secondary pump output flow verification (GPM), network leak detection, bypass-valve control check, hydraulic balancing, and much more.

Flowmeter Verification: In-line flow meters such as turbine or electromagnetic flowmeters suffer from calibration drift over time due to several factors. This drift can cause tremendous measurement errors and as a result it can affect the efficiency of your process/product quality. The 801P ultrasonic flowmeter can be installed adjacent to your existing flowmeters for a quick accuracy check to ensure they are performing within specifications.

Energy Audits: The Uf 801-P ultrasonic flowmeter is equipped with two temperature inputs to measure supply and return temperatures on a cooling/heating system in a building. The temperature kit supplied with the flow meter (optional) includes matched clamp-on temperature sensors to avoid pipe cutting. The temperature readings along with the flow readings can provide accurate energy consumption of your system (kWh). This is a great tool for ESCO’s (energy service companies) to perform energy audits to create energy model of any facility.

Leak Detection: The Uf 801-P ultrasonic flowmeter is also an ideal portable metering solution for water leak detection in network pipes. For instance, the UF801 can sense liquid velocities down to ±0.03 ft/s so even small movement in water at low-peak times can be precisely detected.

Network Metering: Water utility companies and district cooling plants have an extensive water pipe network (underground and above ground). During the design phase a lot of these pipelines are not provided with critical metering points that are required for proper measurement and control of the infrastructure. This portable flow meter can help the operators carry out temporary flow measurements on various points in the network to study the feasibility of adding additional metering points.

The 801P has a robust design for harsh environments and is rated IP68 for complete water and dust protection. With an internal datalogger, all your valuable measurement data is secure in its internal memory and ready for easy transfer to a computer for analysis and reporting.

Other Typical Applications:

› Domestic water: Leakage detection, pump flow control, control of in-line flow meters, etc.

› Water (raw, waste): Pump flow control.

› Flow surveys: Troubleshooting installations, resolving disputes, etc.

› System Commissioning: Validation of system performance before handover of a project.

› HVAC: System balancing, thermal assessment (water for air conditioning and heating systems), etc.

› Hydrocarbons: Temporary flow measurement.

For Related Case Studies:

| Measuring Principle | Transit Time |

| Flow Channels | Single and Dual Channel |

| Accuracy | Up to ±0.5 % of reading |

| Repeatability | ±0.1% |

| Velocity Range | 0 to 30 m/s (0 to 98 ft/s) bi-directional |

| Minimum Operating Velocity | 0.03 ft/s |

| Pipe Diameter Range | DN10 to DN10,000 (0.5" to 390") |

| Pipe Material | Aluminium, asbestos, cast iron, copper, glass, grey cast iron, nylon, Plexiglas, polyethylene, PTFE, PVC, stainless-steel and steel. Other materials can be used if their physical properties are known. |

| Datalogger | Built-in datalogger records between 1 and 30 variables - up to 266,706 lines |

| Battery | Up to 14hr continuous use |

| Protection Rating | IP68 |

| Temperature Range | -10°C to 50°C (14°F - 122°F) |

› Light weight (less than 1kg)

› Easy to use

› IP68 ABS enclosure

› Multi-parameter data logger

› Stores up to 11 configurations/sites

› Timer/programmer

› Optional Input/output modules (analogue, digital)

› Graphic screen

› Echo, gain and quality index displayed

› Battery life up to two months, using timed operation

› Automatic zero calibration

› Ten flow calculations per second

› On every type of homogeneous liquid, even non-conductive

› On most types of gases – high and medium pressure*

› Non ideal flow conditions taken into account