TRIME® GWs Grain Moisture Sensor for grain dryers. Achieve accurate, continuous grain moisture measurement. Improve efficiency and lower grain drying costs.

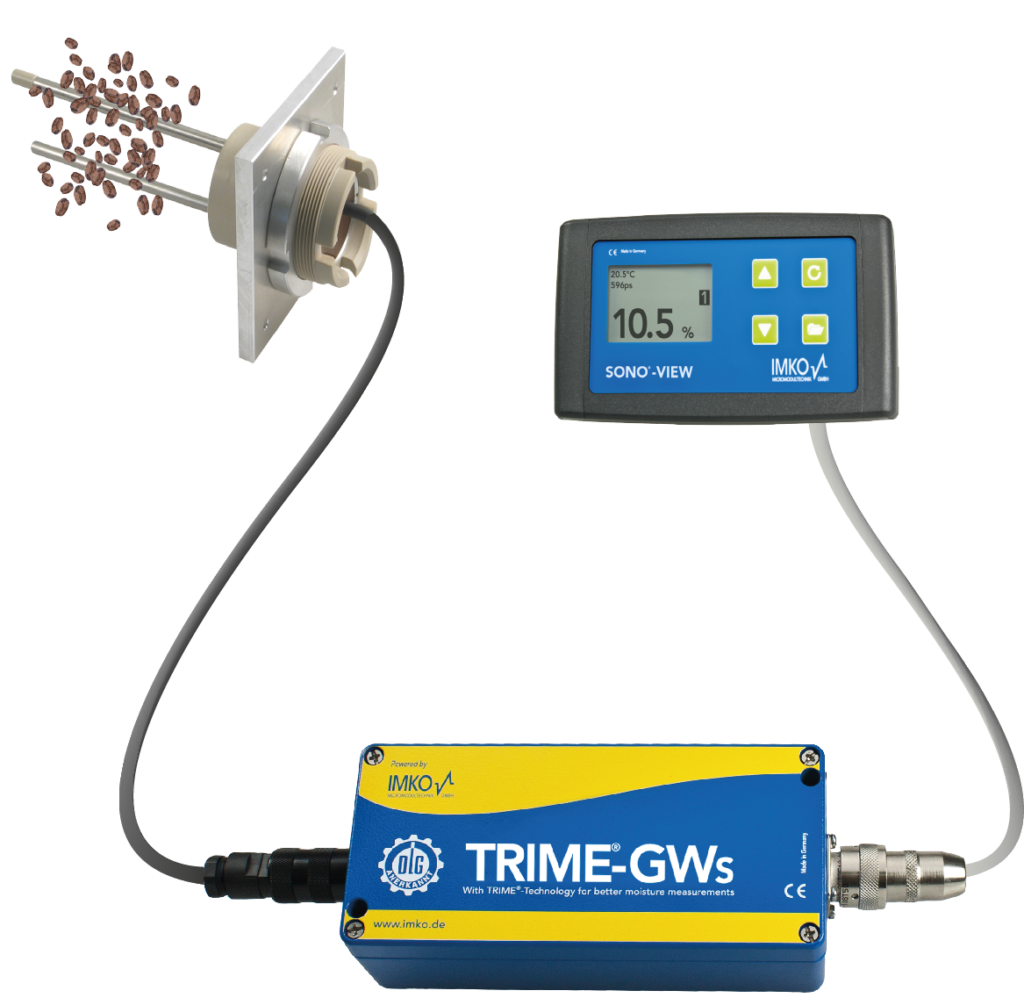

The innovative TRIME® GWs Grain Moisture Sensor is designed to provide accurate and continuous moisture measurements directly in grain dryers, handling process temperatures up to 120°C (248°F). This advanced TDR grain moisture sensor is ideal for monitoring materials such as corn, rice, wheat, cereals, oil seeds, pulses, dried fruit, animal feed, cat food, dog food, woodchips, powders, granulate, and any other type of grain.

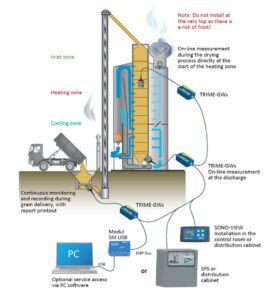

With the TRIME® GWs Grain Moisture Sensor, you can efficiently monitor grain moisture during material delivery and automate moisture control in kiln drying processes. This grain dryer moisture sensor enhances drying precision, ensuring optimal moisture levels for storage and preventing mold formation.

TRIME® moisture sensing rods create a wide magnetic field, increasing penetration depth in the material to provide higher measurement accuracy and stability. The flexible probe design of this grain moisture sensor is suitable for various applications, ensuring reliable performance across different grain types and conditions.

The GR rod-probe requires good flowability of the measured material to ensure proximity to the rods during flow. For applications with poor material flowability, we offer tailored solutions to meet your specific needs.

Grains often contain excess water when harvested, which can lead to mold and product loss during storage. The TRIME® GWs Grain Moisture Sensor is perfect for vertical dryers, measuring input moisture to determine the water quantity to be removed. This helps control dwell time and throughput rate based on dryer performance, preventing over-drying and energy waste.

With the TRIME® GWs Grain Moisture Sensor, you can directly monitor product moisture during the drying process without taking samples. This eliminates the need for indirect measuring methods, such as exhaust air humidity or temperature readings. By directly measuring the water content, you can continuously monitor and optimize your drying process control.

› Direct moisture measurement in the material, even in hard-to-reach places.

› Continuous recording and monitoring of moisture content and temperature.

› Enhanced process control during all drying steps.

› Improved process stability leading to lower product losses (over-drying/under-drying).

› Cost savings due to improved energy efficiency from reduced over-drying.

Experience the next level of drying efficiency with the TRIME® GWs Grain Moisture Sensor. Ensure your grain is perfectly dried and stored, maximizing quality and minimizing losses. Contact us today for a quote.

| Measuring range | 5..45% by weight (b.w.) on a wet mass basis |

| Repeatability | 0.3 % b.w. |

| Probe temperature range | 0..127°C; temporarily up to 150°C |

| Measuring period / -interval | floating average with adjustable time interval |

| Interface | RS485 and IMP-Bus |

| Analogue output | 0(4)...20 mA = 0 .. 100% gravimetric moisture |

| Housing protection | Aluminium diecasting IP65 |

| GR-Probe protection | IP68 watertight casting |

› Determination of grain and product moisture directly in the dryer

› Inline measurement within the process at temperatures up to 130°C

› Continuous measurement for higher process efficiency

› Cost savings as over- and under-drying treatment eliminated

› Measuring range up to 70% moisture

› Resolutions in dry area up to 0.05%

› Different probes for each application and demand

› Trouble-free system connection to SCADA

› Product temperature with an integral temperature sensor

› Optimized workflows with cost savings

› Special PEEK material for food industry

› Robust probe designs for long-term use under extreme conditions

› Independent of grain type, temperature of material, and ionic conductivity